Transmitting driving thrust to the vehicle body and controlling axle torque reaction

When the vehicle is powered forwards by the engine and transmission system, a force is applied to the rear wheels. This force must be harnessed to provide forward movement. The vehicle body or chassis provides this by taking the force generated by the transmission system and engine.

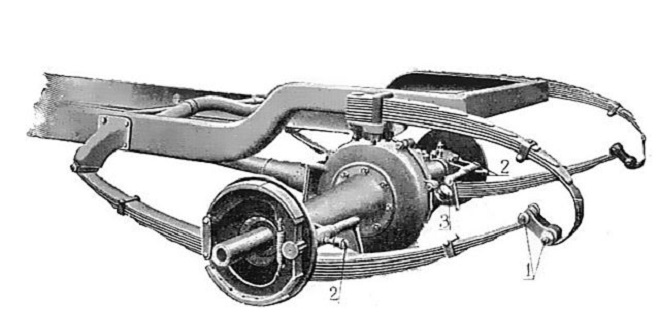

Hotchkiss open-type drive system

This once-popular arrangement. Two rear leaf springs, longitudinally mounted, are connected to the frame by a ‘fixed pivot at the front, and swinging shackles at the rear. A universal joint is fitted at each end of the exposed or ‘open’ type propeller shaft, with provision made for alteration in shaft length, which occurs when the springs are deflected.

Torque reaction is resisted by damping the axle to the springs by means of ‘U’ bolts. Under heavy driving conditions, the springs will deflect up at the front and down at the rear, and vice versa during braking. This movement will help to damp driving shocks and improve transmission flexibility. Since the axle continually moves up and down, the need for a rear universal joint is clear.

Driving thrust is transferred from the casing to the spring by the friction between the two surfaces and then transmitted through the front section of the springs to the vehicle frame. If the ‘U’ bolts become loose, the spring centre bolt (axle location bolt) will have to take the full driving thrust, and the high shearing force will quickly fracture it.

Torque-tube drive system

Whereas the Hotchkiss drive system uses stiff springs to resist torque reaction and driving thrust, the torque tube or enclosed drive relieves the springs of all duties other than their intended purpose. This means that a ‘softer’ ride can be achieved by using either ‘softer’ springs or another form of spring, for example helical.

Bolted rigidly to the axle casing is a tubular member, which is located at the front by a ball and socket joint positioned at the rear of the gearbox or cross-member of the frame. Bracing rods, connected between the axle casing and the torque tube, strengthen the construction. A small diameter propeller shaft is fitted inside the torque tube and splined to the final-drive pinion. Mounted in the centre of the ball joint is a universal joint to allow for angular deflections of the drive.

In this arrangement, the torque reaction and driving thrust are taken by the torque tube. When the forward thrust from the ball is taken on the rear housing of the gearbox, means must be provided to transfer this force through the gearbox mountings to the frame.

de-Dion drive system

The de-Dion axle is often regarded as the halfway stage between the normal axle and independent suspension. Many of the advantages of the latter are achieved in this layout, but since the rear wheels are still linked by an axle tube the system cannot be classed as independent.

Last word

Each spring carries a hub mounting, which is rigidly connected to a tubular axle beam that supports the wheel on a stub axle shaft. Bolted to a cross-member of the frame is the final-drive unit, and from this, the drive is taken through two universally jointed shafts to the wheels. The main propeller shaft is fitted with a universal joint at each end to allow for flexing of the frame.

Revamping your menu is crucial to meeting the ever-changing demands of your customers. By updating your offerings, you can cater to new dietary preferences and emerging food trends. Keeping up with the latest dining preferences is essential to staying competitive in the restaurant industry. By adapting your menu, you can attract new customers and retain existing ones, ultimately boosting your business’s success. Whether it’s incorporating plant-based options or highlighting locally sourced ingredients, being attentive to dining trends can enhance your restaurant’s appeal.