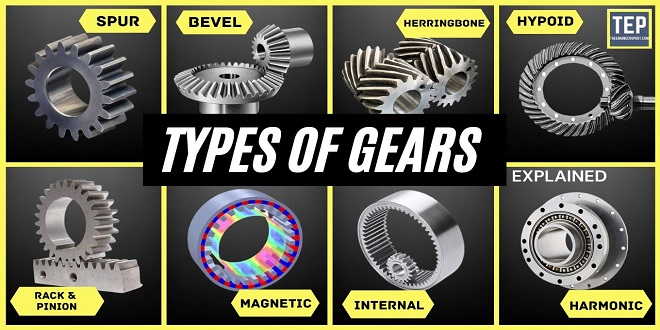

Different types of gears and gearboxes

Types of gearing

Various types of gearing are used on a motor vehicle, but gearboxes employ one or more of the following:

1 Spur gears – teeth parallel to the axis, used on a sliding-mesh gearbox. Mainly in the reverse gear system.

2 Helical gears – teeth inclined to the axis to form a helix. Gives increased strength and quieter operation.

3 Double helical gears – two sets of opposing helical teeth.

4 Epicyclic or planetary gears – spur or helical gears rotating about centres that are not stationary.

Gear material

The gear teeth have to resist severe shock loading and wear, so case-hardened steel is used to provide a tough core and a hard surface.

Manual gearboxes

Gearboxes today may be divided into two main groups: manual and automatic. Manual gearboxes require the driver to have full control of the gearbox. Usually, the driver will use a manual control lever to select the most appropriate gear ratio to suit the driving conditions. This has been developed further with the use of automated selecting manual gearboxes. This type of gearbox operates as a manual gearbox but has electronic or hydraulic gear shifting devices. This can speed up the gearshift and also allow the driver to have automatic gear shifting.

Automatic

The term ‘automatic gearbox’ refers to a gearbox type that is able to change gears without the aid of the driver throughout the vehicle operating conditions. Once the driver has made the initial selection to determine the direction in which the vehicle is to move (Figure 3.8) and the gear range to be used, the other decisions are made by the transmission control module or ‘brain’ within the gearbox.

Continuously variable transmission

The power output of a normal engine varies with the engine speed. At slow speeds, the output is very low, so if good vehicle performance is required, the engine would have to rotate much faster; it would need to operate at a speed at which it develops its maximum power.

This story is repeated when the torque output and fuel economy are considered. Maximum torque occurs at a different speed from that for maximum economy, and neither of these speeds coincides with the point of maximum power.

This constant engine-speed requirement for the achievement of any one of the three performance factors is not possible with a conventional gearbox; this is because the engine speed has to be continually changed to suit the vehicle speed. As a result, the engine only gives its best at the vehicle speed appropriate to the point of maximum engine torque, power or economy.

Stepped transmission

This graph indicates why the term ‘stepped transmission’ is used to describe any system that gives this kind of stepped output. Increasing the number of ratios gives a considerable improvement and this is used on many heavy vehicles, as well as modern passenger vehicles, although passenger vehicles will incorporate fewer gear ratios than heavy vehicles. When the number of ratios is increased to about 10, the combination of the narrow engine range needed to ‘bridge the gap’ between the ratios, and the close approximation of the actual tractive curve to the ideal, allows the engine to be operated around its best speed.

Last word

An approach to the ideal tractive effort curve is achieved by using an automatic gearbox with a torque converter. Although the converter is very inefficient at low engine speeds, the effect of the converter’s infi nitely variable ratio between the limits of about 2 : 1 to 1 : 1 gives a smooth transition and positive drive between the stepped ratios of the main automatic gearbox.