Technology

Why Precision is Key: The Advantages of CNC Machining for Complex Parts

Advantages of CNC Machining for Complex Parts

- Increased accuracy: Huapin CNC machining can produce parts with extremely tight tolerances. This is because the cutting tools are controlled by computer-generated instructions, which are much more precise than human hands.

- Repeatability: Huapin CNC machined parts will be identical every time they are produced. This is due to the fact that the same instructions are used each time the part is made.

- Faster production times: CNC machines can produce parts faster than traditional manufacturing methods, such as hand sculpting or casting.

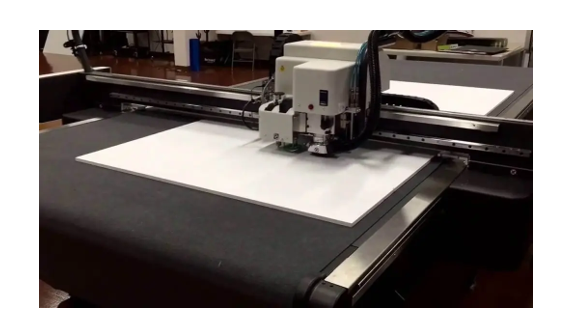

Different Types of CNC Machines

- Vertical Machining Centers (VMCs): A VMC is great for milling, drilling, and tapping operations. It can also handle light turning and grinding work. VMCs have a smaller footprint than other types of CNC machines, so they’re perfect for small shops with limited space.

- Horizontal Machining Centers (HMCs): HMCs are ideal for large, heavy workpieces that require high rigidity and precision. They can handle complex machining operations, including milling, drilling, boring, and reaming.

- Universal Machining Centers (UMCs): As the name suggests, UMCs can perform a variety of machining operations. They’re perfect for small to medium-sized workpieces that require high accuracy and repeatability.

Conclusion

CNC machining is a great option for the production of complex parts that require precise dimensions and tolerances. It offers numerous advantages over traditional methods, such as better accuracy and repeatability, reduced waste, and faster turnaround times. With its ability to produce high-quality products with minimal human intervention, CNC machining has become increasingly popular in many industries.